Data Acquisition on Packaging Machines in the Pharmaceutical Industry

This customer is manufacturing packaging machines for pharmaceutical products. The machines produce containers like ampoules, bottles, vials or single-use syringes which contain the appropriate medical products as well. These machines have to be compliant to the FDA standards.

Application / Problem:

The customer is manufacturing complete customized machines and production lines for high volume production of many different medical packaging systems. In order to verify the proper functioning of the production line the manufacturer is performing a quality test before the plant is delivered to the customer. The objective of the test measurement is to confirm that the equipment is working to its standards and that that the sterilisation processes is also meeting the required standards. In the past the acceptance test measurement and documentation was based on a mainly manually data recoding process and the report was also manually generated in Excel. The customer was looking for a solution to simplify the data recoding and to automated the report generation.

Proposal / Solution / Hardware:

The customer decided to take Expert Key 200 data acquisition systems and to order a customised ProfiSignal Klicks application for the data acquisition process and the automated reporting.

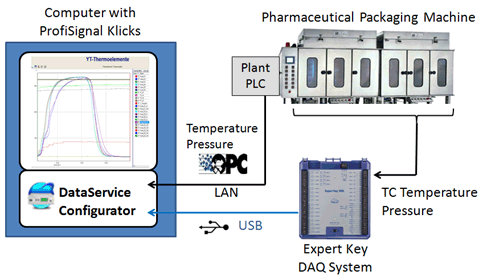

The data acquisition project is based on a universal ProfiSignal application which is independent of the connected data acquisition hardware. The user can record data from the analog inputs of the Expert Key and record values from the machine PLC system via OPC server at the same time. The data recoding application is based in measurements from dedicated thermocouple and pressure sensors which are connected directly to the Expert Key 200 unit and on temperature and pressure readings from the Siemens S7 PLC which are interfaced to the DataService Configurator via OPC Server.

The functional design:

The application is divided into 2 separate ProfiSignal Klicks programs:

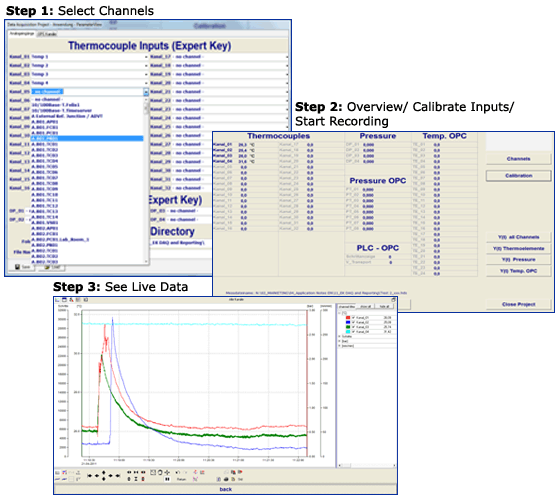

- Program is dedicated to record the data from the Expert Key unit and the machine Siemens S7 PLC via OPC server.

- Program is dedicated to analyse the recoded data and to automatically generate a test report.

Recoding Application:

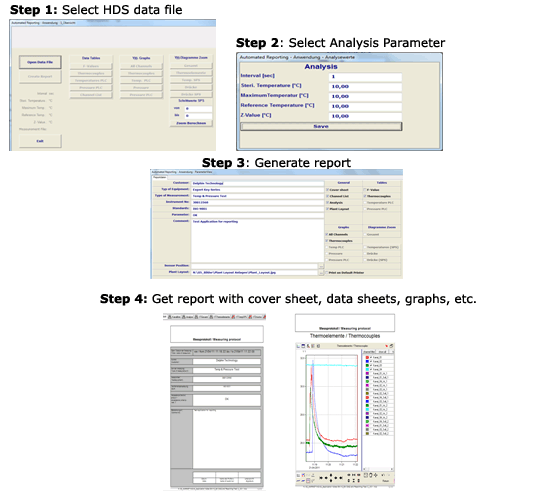

Reporting Application:

Benefits:

The interesting feature of this apparition is that the ProfiSignal Klicks application was developed in a way that the customer can record data of any hardware which is connected to the DataServiceConfigurator. The customer can connect channels from any DAQ device like Expert Key, TopMessage, LogMessage, ProfiMessage or any third party devices from (VTI, HBM, PSI; Adam Module, DataTranslation etc..) which are supported by a driver. The ProfiSignal application records data from the Expert Key hardware and reading from the PLC via the OPC interface into one HDS data file. The user can also perform an offset calibration of each channel if required. The data recoding is performed completely independently from the data analysis and report generation.

The Report is generated from the recorded HDS file. The Report is of course tailed to the requirement of this specific customer and the application also calculates special key indicators which show whether the production equipment is working correctly and meets the sterilisation requirements in terms of temperature level and duration. The quality of the sterilisation process is expressed by the F-value.

The Key benefits:

-

The Expert Key is used as a universal high speed DAQ system to verify the performance of new packaging systems.

-

Also maintenance technician in the field us the Expert Key to determine the performance of the equipment during operation.

-

The data recoding application is separated from the data analysis application which gives the customer more flexibility.

-

The whole solution is able to record data from DAQ modules and also from the Siemens S7 PLC via OPC server into one data file.

-

The report generation is fully automated and standardised to save time and to reduce errors compared to the previous Excel reporting system.

For more information please see: Expert Key >>

Have a question?

{rsform 2}

English

English  Lietuvių

Lietuvių  Русский

Русский